Paper industry

Individual solutions for the paper industry

At Wefapress, we are proud to have worked closely with the paper industry for several decades. Our many years of experience and extensive practical trials have enabled us to develop high-quality products that are specifically tailored to the requirements of the paper industry. From the screening table front bar to the milled covering in perforated or slotted design, we guarantee the suitability of our products.

Our products are made from pure, ultra-high molecular weight low-pressure polyethylene (PE-UHMW) without the addition of regenerates. By using lubricants and special additives, we have developed material qualities that are even more wear-resistant. Thanks to the press sintering process, we can ensure a stress-free internal structure and produce workpieces up to 10 meters long without welds.

Optimum dewatering in the wet end of a paper machine for maximum efficiency.

- Highest wear resistance => Long service life

- Low coefficient of friction

Plastic materials for the Paper industry

Application areas

- Diffuser block

- Drainage elements

- Sealing strips for suction rolls

- Format delimiter

- Scraper blades

- Gears

- Profiles and guides

- Sieve lifter

- Rotary distributor

- Components in the wet end of paper machines

- Individual solutions

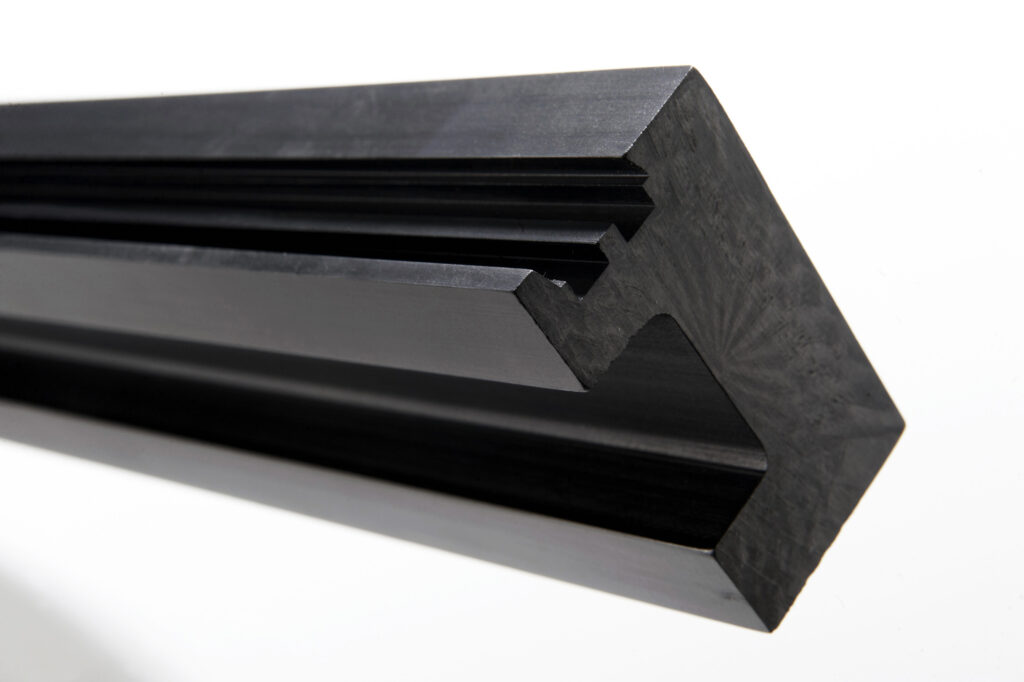

Diffuser block

Our diffuser blocks are specially designed for the paper industry and offer an efficient and reliable solution for your production processes. They are made of high quality plastics and offer excellent resistance to wear and corrosion.

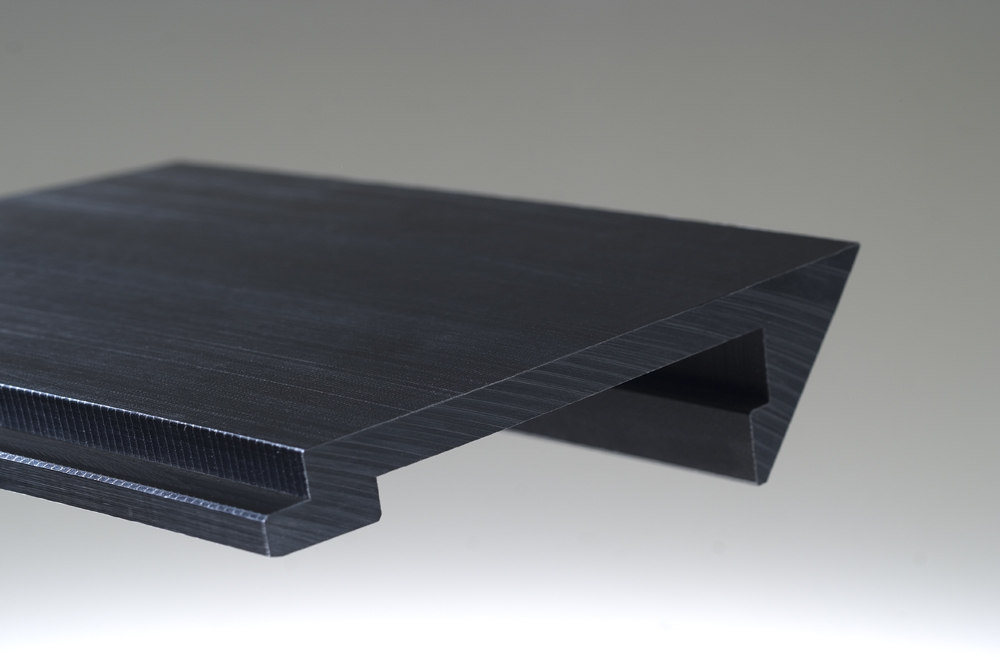

Drainage elements

Our dewatering elements are an essential part of the papermaking process. They help to remove the water from the paper pulp and thus contribute to improving the efficiency and quality of the final product.

Scraper blades

Our doctor blades are specially designed for the paper industry and offer an efficient and reliable solution for roll cleaning. They are made of high quality plastics and offer excellent resistance to wear and corrosion.

Sealing strips for suction rolls

Our sealing strips for suction rolls are an essential part of the papermaking process. They provide an efficient and reliable seal to ensure the quality and consistency of the final product.

Rotary distributor

At Wefapress, the focus is on the production of perforated plates for rotary distributors. With the ability to produce perforated plates as a monoblock up to a diameter of 2,500 mm and a thickness of 200 mm, we are setting new standards in the industry. Our precise step bore surfaces provide optimal conditions for rotary distributors.

Gears

Our screen lifters are an essential part of the papermaking process. They help prevent stock suspension run-out and ensure uniform basis weights and fewer edge tears, which contributes to smooth paper machine operation.

Contact us

Do you have questions or need more information? We are here for you personally and look forward to hearing from you.